Usage range from decorative furnishing to construction.

Adjustments to the manufacturing process can impart differences in thickness, panel size, strength, and rigidity. OSB panels have no internal gaps or voids, and are water-resistant, although they do require additional membranes to achieve impermeability to water and are not recommended for exterior use. The finished product has properties similar to plywood, but is uniform and cheaper. When tested to failure, OSB has a greater load-bearing capacity than milled wood panels. It has replaced plywood in many environments, especially the North American structural panel market.

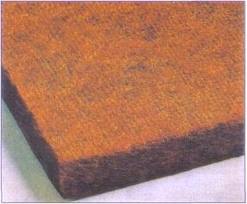

While OSB does not have a continuous grain like a natural wood, it does have an axis along which its strength is greatest. This can be seen by observing the alignment of the surface wood chips. The most accurate method for determining the axis of strength is to examine the ink stamps placed on the wood by the manufacturer.

All wood-based structural use panels can be cut and installed with the same ease and types of equipment used with solid wood.

Some manufacturers treat the wood chips with various borate compounds which are toxic to termites, wood boring beetles, molds, and fungi, but not mammals in applied doses.

12.0MM X 1220MM X 2440MM