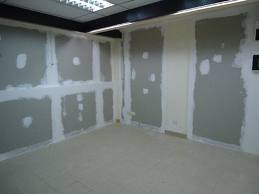

Drywall (also known as plasterboard, wallboard or gypsum board) is a panel made of gypsum plaster pressed between two thick sheets of paper. It is used to make interior walls and ceilings. Drywall construction became prevalent as a speedier alternative to traditional lath and plaster.

A wallboard panel is made of a paper liner wrapped around an inner core made primarily from gypsum plaster. The raw gypsum, CaSO4·2 H2O, (mined or obtained from flue-gas desulfurization (FGD)) must be calcined before use to produce the hemihydrate of calcium sulfate (CaSO4·½ H2O). This is done in kettle or flash calciners, typically using natural gas today. The plaster is mixed with fiber (typically paper and/or fiberglass), plasticizer, foaming agent, finely ground gypsum crystal as an accelerator, EDTA, starch or other chelate as a retarder, various additives that may increase mildew and/or fire resistance (fiberglass or vermiculite), wax emulsion or silanes for lower water absorption and water. This is then formed by sandwiching a core of wet gypsum between two sheets of heavy paper or fiberglass mats. When the core sets and is dried in a large drying chamber, the sandwich becomes rigid and strong enough for use as a building material.

Drying chambers typically use natural gas today. To dry 1 MSF ( 1,000 square feet (93 m2) ) of wallboard, between 1.75 and 2.49 million BTU is required. Organic dispersants/plasticisers are used mainly to reduce the amount of water, hence reduce the eventual drying time, needed to produce gypsum slurry flow during wallboard manufacture.

12.0MM X 1220MM X 2440MM